Automated Visual Quality Inspection

60% reduction in manual inspection labor

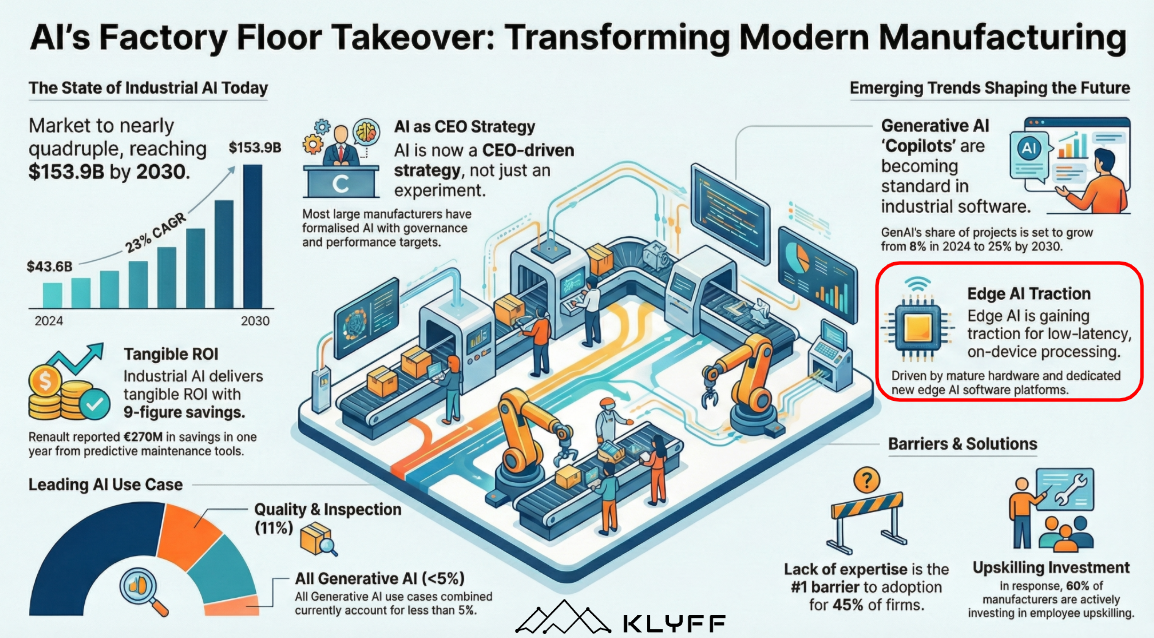

Problem Statement

Manufacturing companies spend millions annually on manual visual inspection. Workers get fatigued, accuracy drops, and productivity suffers. Machine vision can help—but only if you can deploy it quickly and cost-effectively.

Solution

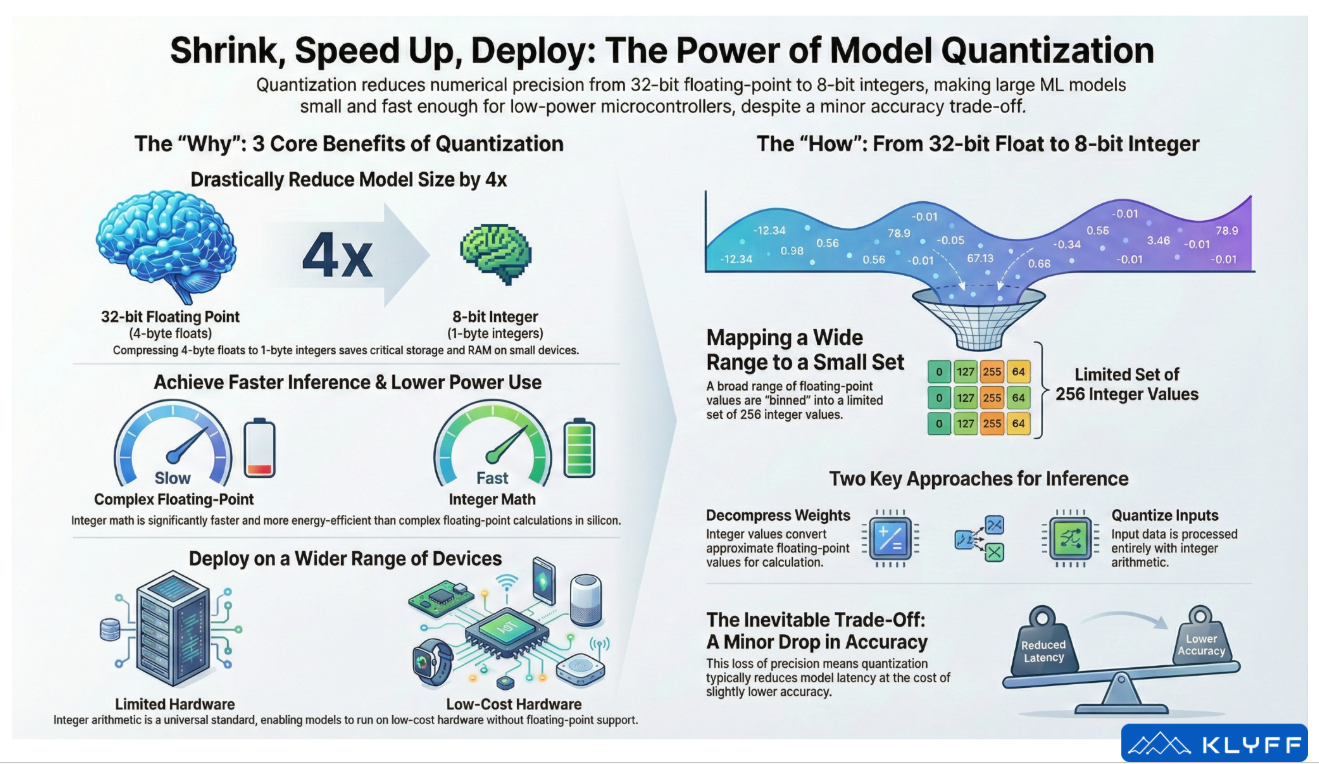

Klyff brings production-ready defect detection to your factory in 8-12 weeks. Real-time, 95%+ accurate detection of solder joints, surface defects, packaging issues—without cloud complexity.

$50K-$150K

Annual savings in the first year

60%+

Reduction in inspection labor (freeing workers for higher-value tasks)

3 Months

Payback period thus resulting in immediate ROI

95%+

Defect detection accuracy

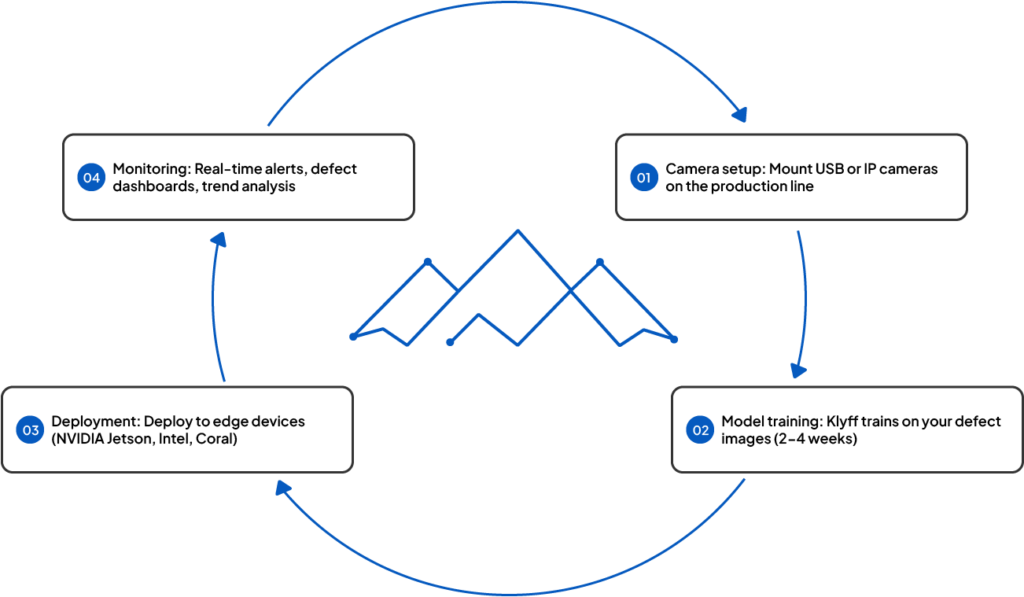

How It Works

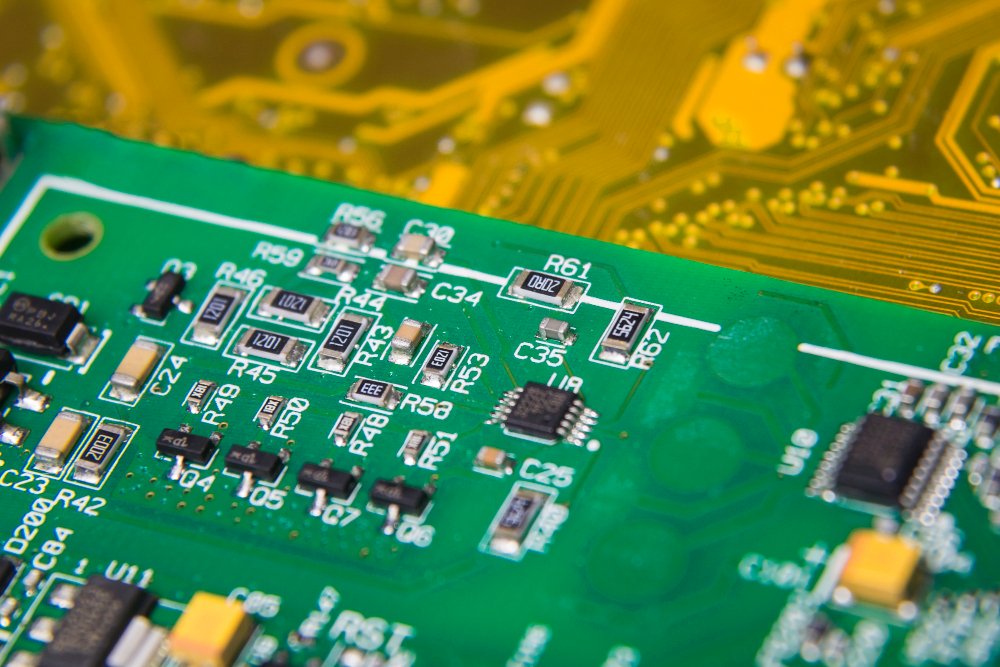

PCB assembly Solder joint inspection

Metal fabrication Surface defects, Scratches

Textile manufacturing Pattern/Color consistency

Food & beverage Packaging quality, Labeling

Electronics assembly Component verification

Case Study

Company: EMS Manufacturing Co.

Industry: PCB Assembly (500+ production lines)

Challenge: 50 QA inspectors verifying solder joints manually — $3M/year labor cost

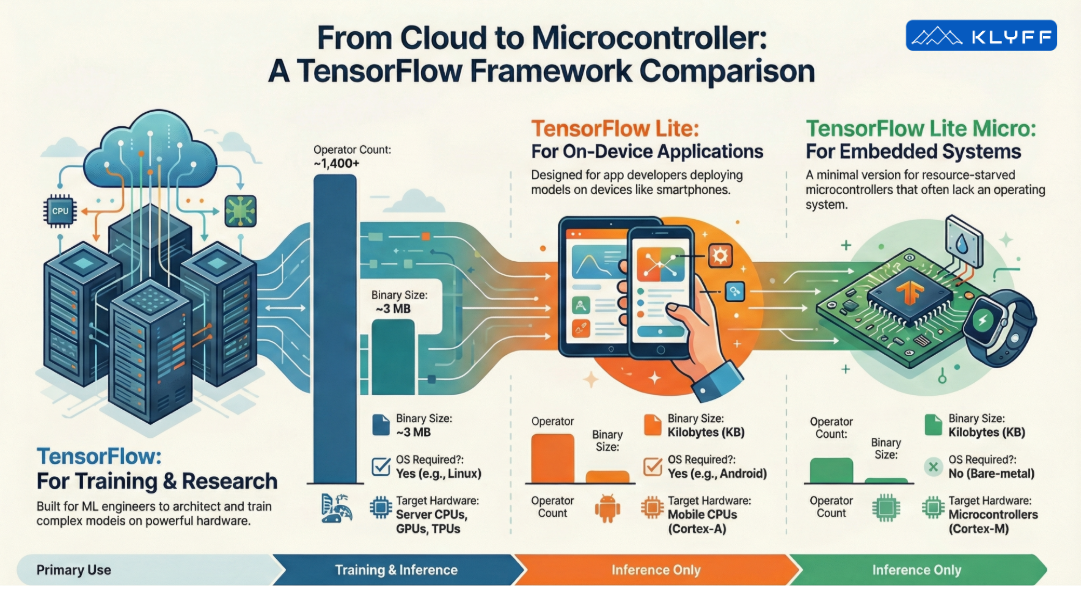

Solution: Klyff defect detection on 5 Jetson Orin devices

Results:

- 60% reduction in inspection labor (30 inspectors freed)

- 98% defect detection accuracy (better than manual)

- 6-week deployment

- $1.8M annual labor savings

- 3-month ROI

“Klyff was a game-changer. We were skeptical about AI quality control, but the accuracy is excellent and the deployment was incredibly fast. In 6 weeks, we had real-time defect detection running on our lines. Our inspectors now focus on edge cases and problem-solving instead of routine inspection. Best investment we made in 2025.”

— John Miller, Quality Director, EMS Manufacturing

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection