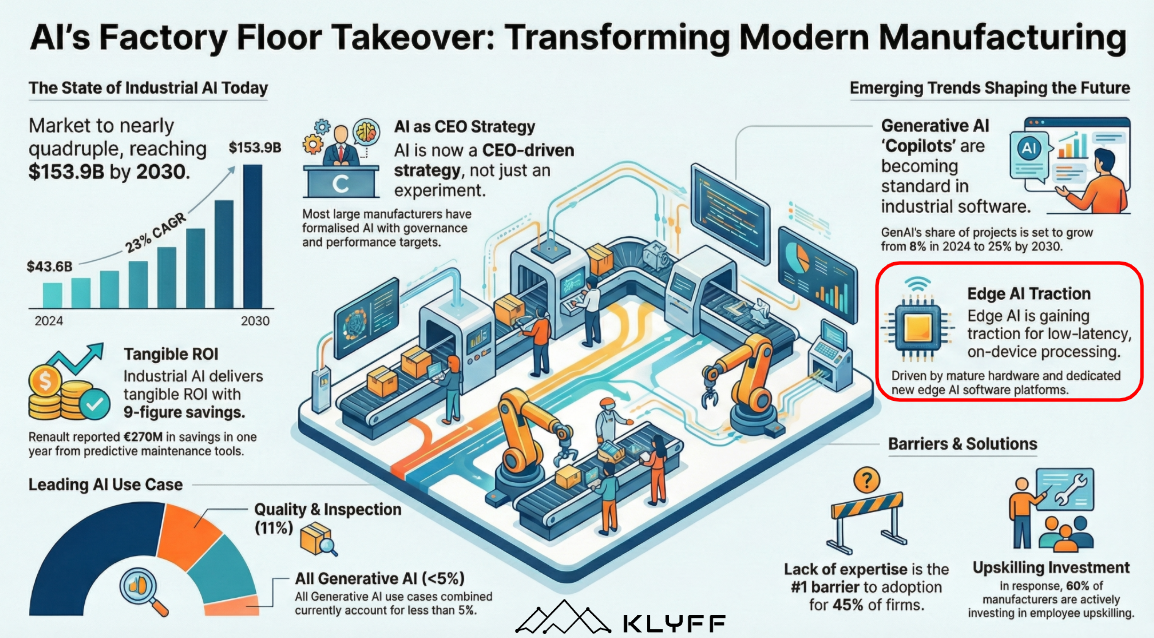

Predictive Maintenance Architecture

Operations teams targeting equipment reliability within 8-12 weeks

What we do:

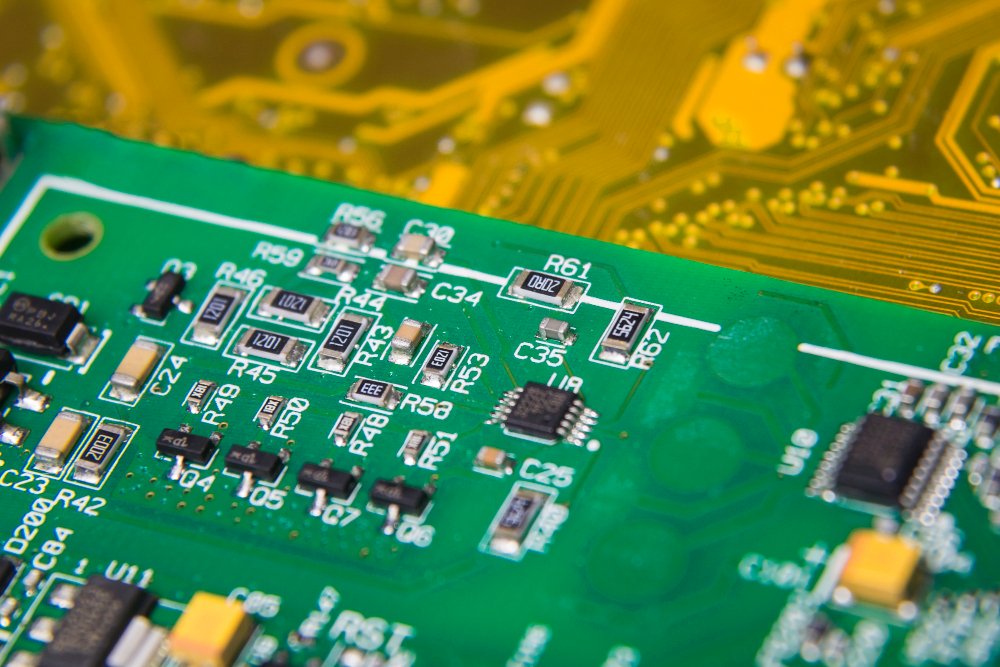

Sensor strategy & placement recommendations

Klyff works with your maintenance and engineering teams to identify critical assets (pumps, motors, bearings, conveyors) and recommend sensor types and locations that maximize early fault detection.

Tri-axial accelerometers near rotating equipment for vibration, temperature probes on housings and fluid lines, and acoustic sensors positioned to detect cavitation, friction, or grinding sounds.

Proper placement and sensor selection ensure that mechanical degradation signatures (imbalance, misalignment, looseness, bearing wear) are captured with a high signal-to-noise ratio, enabling early warnings before catastrophic failure.

Feature engineering (vibration, temperature, acoustic analysis)

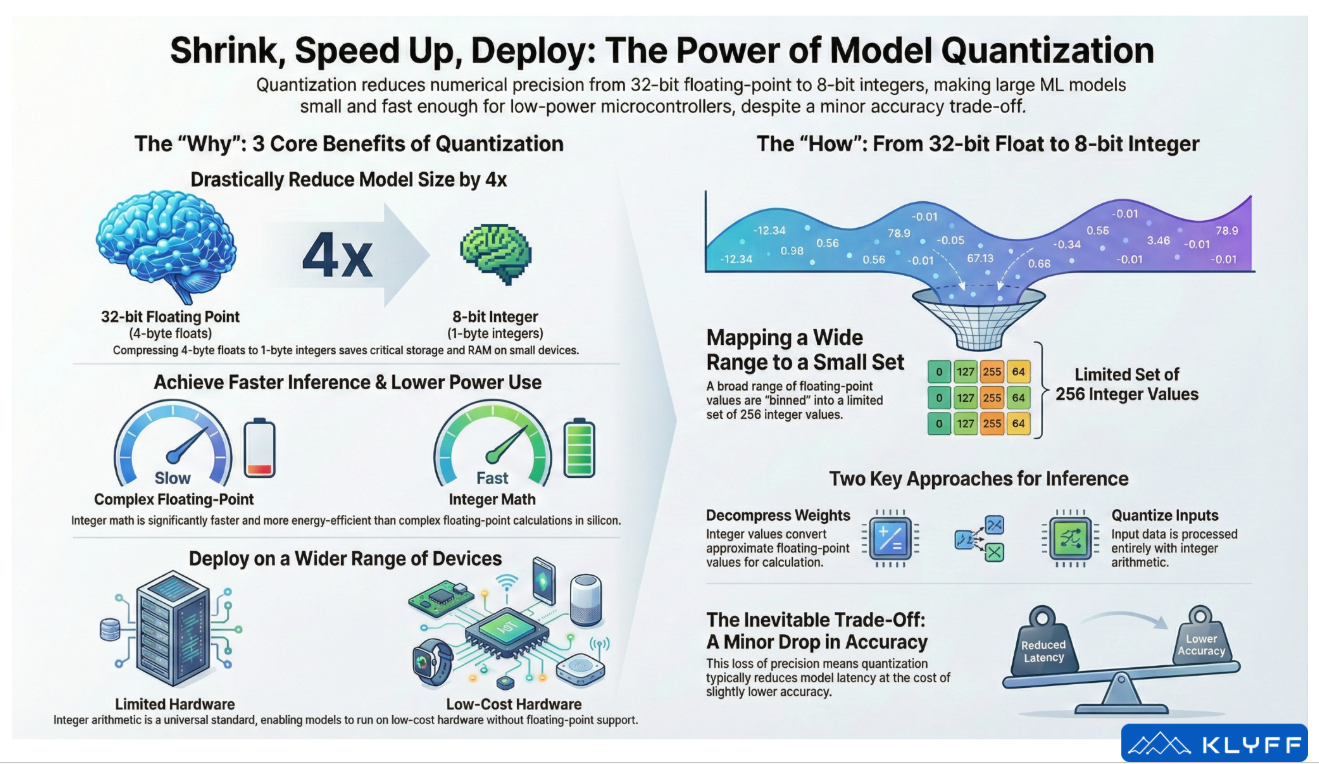

Raw sensor streams are transformed into actionable features.

RMS and peak vibration amplitude, spectral bands via FFT, envelope analysis for bearing faults, kurtosis and crest factor for impulsive events, temperature gradients, and acoustic spectrograms for cavitation or friction detection.

These engineered features compress high-frequency sensor data into compact, interpretable inputs that highlight mechanical wear, lubrication degradation, and process anomalies, feeding directly into anomaly detection models.

Anomaly detection model training

Unsupervised or semi-supervised machine learning models (autoencoders, isolation forests, one-class support vector machines) are trained on baseline data from healthy equipment operation to learn normal behaviour patterns.

During production, real-time deviations from this learned baseline are flagged as anomalies—enabling early warnings even when labelled failure data is scarce or when failure modes are novel.

The result is predictive maintenance that does not require historical failure datasets, making it practical for newer assets or rare fault types.

Threshold optimization & alerting setup

Alert thresholds are carefully tuned using pilot production runs and historical incident data to balance sensitivity (catching faults early) against false positives that would trigger alert fatigue and reduce trust.

Multi-level alerting strategies are configured—warning (investigate), critical (plan maintenance soon), and shutdown (stop immediately)—with clear escalation paths to operators, maintenance teams, and planners, ensuring alerts are actionable and aligned with your risk tolerance and production SLAs.

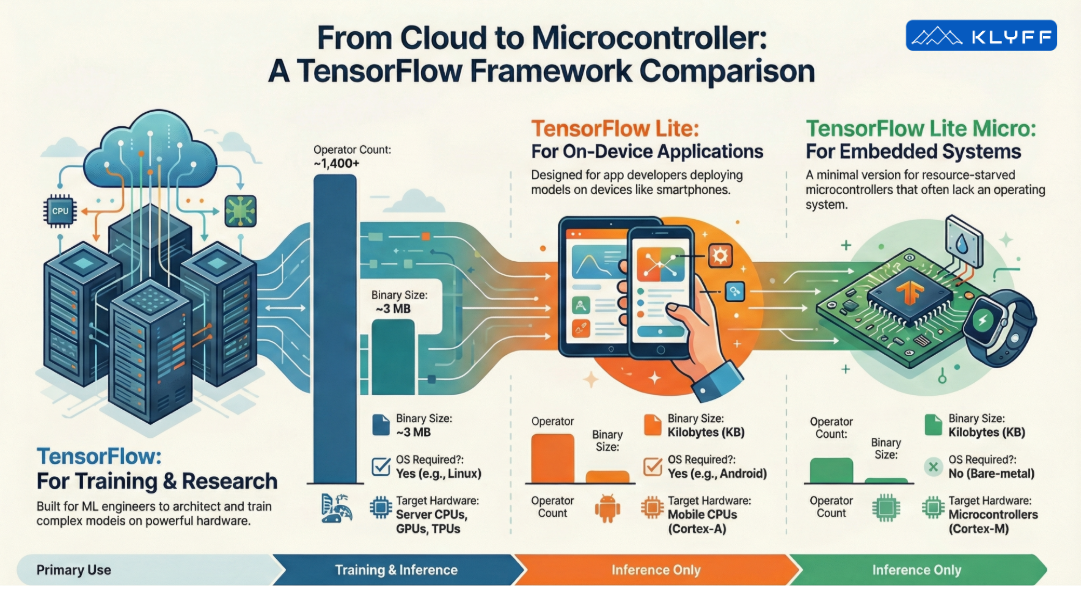

Privacy-preserving design (zero cloud)

All data processing, feature extraction, anomaly detection, and inference run locally on edge devices, factory servers, or private on-premises infrastructure.

Raw vibration, acoustic, and temperature data never leave your facility or cloud.

Only aggregated health scores, anomaly flags, and maintenance recommendations are optionally shared across sites for fleet-level insights, enabling multi-plant learning while maintaining strict data sovereignty, trade secret protection, and regulatory compliance (GDPR, IEC 62304).

Expected outcomes:

Deployment Ready

Predictive Maintenance system design

$250K-$500K

Annual savings potential

70%

Unplanned downtime reduction

100%

Team training and SOPs

Our engagement process:

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection