Federated Learning for Multi-Site Fleets

Multi-facility manufacturers within 12-16 weeks

What we do:

Multi-site architecture design

Klyff designs a distributed system where each manufacturing site runs a local inference and training environment on its own edge hardware or on-prem servers, connected to a secure central orchestrator that coordinates model updates without centralizing raw data.

The architecture accounts for network reliability, latency, and bandwidth constraints typical in industrial settings, utilizing an asynchronous model aggregation approach so that slow or offline sites do not impede the fleet’s ability to learn.

This design enables scalability across dozens or hundreds of plants without building a costly centralized data lake.

Privacy-preserving aggregation setup

Rather than sending raw production data to a central server, each site trains a local model and sends only the model weights (parameters) or gradient updates to the aggregator, where they are averaged to produce a global model that benefits from all sites’ data without exposing proprietary process details or production secrets.

Differential privacy techniques add calibrated noise to gradients, ensuring that even the aggregator cannot reverse-engineer individual site data or defect patterns.

This approach satisfies data residency, GDPR, and trade secret protection requirements while unlocking cross-site learning.

Per-site customization

While the global federated model provides a strong baseline trained on patterns from all sites, each location can fine-tune or adapt the model to its own equipment vintage, process parameters, and local defect classes—for example, one plant’s older conveyor system or another’s newer precision sensor.

Klyff manages model versioning and local adaptation, ensuring that site-specific customizations improve local accuracy without degrading the global model’s generalization.

Federated model training & versioning

Klyff orchestrates rounds of federated training: each site trains on its local data, uploads model updates, the server aggregates them into a new global model, and the updated model is pushed back to all sites for the next round.

Strict versioning ensures reproducibility, rollback capability, and audit trails—critical for quality assurance and regulatory compliance in manufacturing.

Training typically runs in bi-weekly or monthly cycles, allowing rapid convergence while respecting operational constraints.

Ongoing optimization (3-6 months)

After initial deployment, Klyff monitors federated model performance across all sites, identifies drift in local environments (equipment changes, new defect types), and iteratively retrains the global model and site-specific adapters.

Over 3–6 months, this continuous feedback loop drives significant accuracy improvements—often 5–15% gains—as the model learns from the aggregate experience of all plants and adapts to emerging failure modes or seasonal variations.

Regular reporting and dashboards track per-site and fleet-wide KPIs, ensuring transparency and ROI validation.

Expected outcomes:

Collective Intelligence

Across multiple factories

40%

Faster model improvement

Data sovereignty

Zero Data leaves the sites

100%

GDPR/HIPAA compliant

Our engagement process:

Selected Customer Success Stories

Adaptive Predictive Maintenance

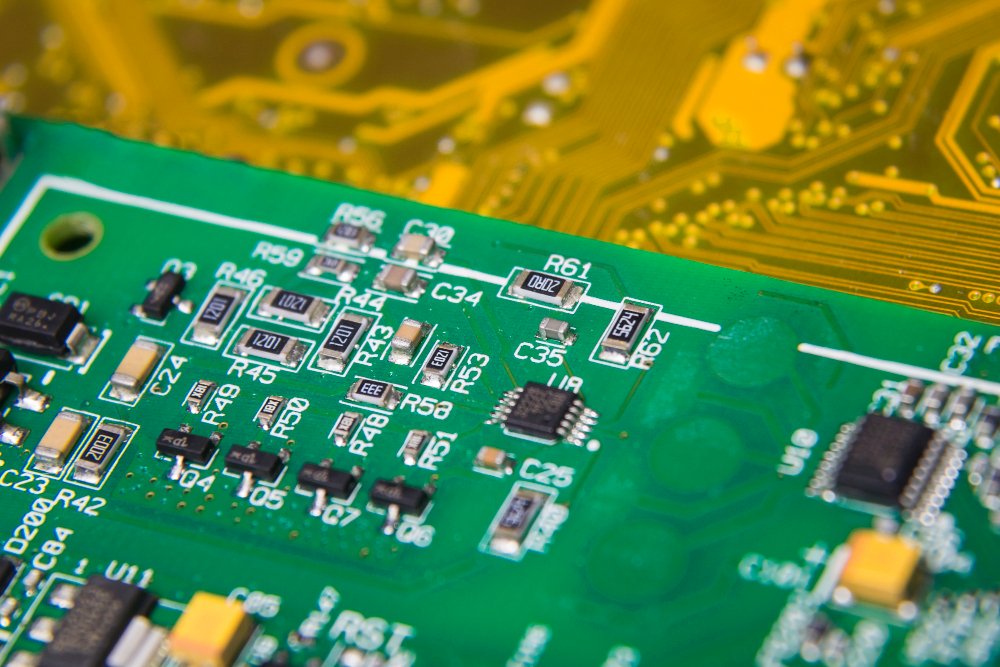

Solder Joint Inspection