Manufacturing Intelligence™

For industrial OEMs and operators with fleets of cameras, robots, and sensors

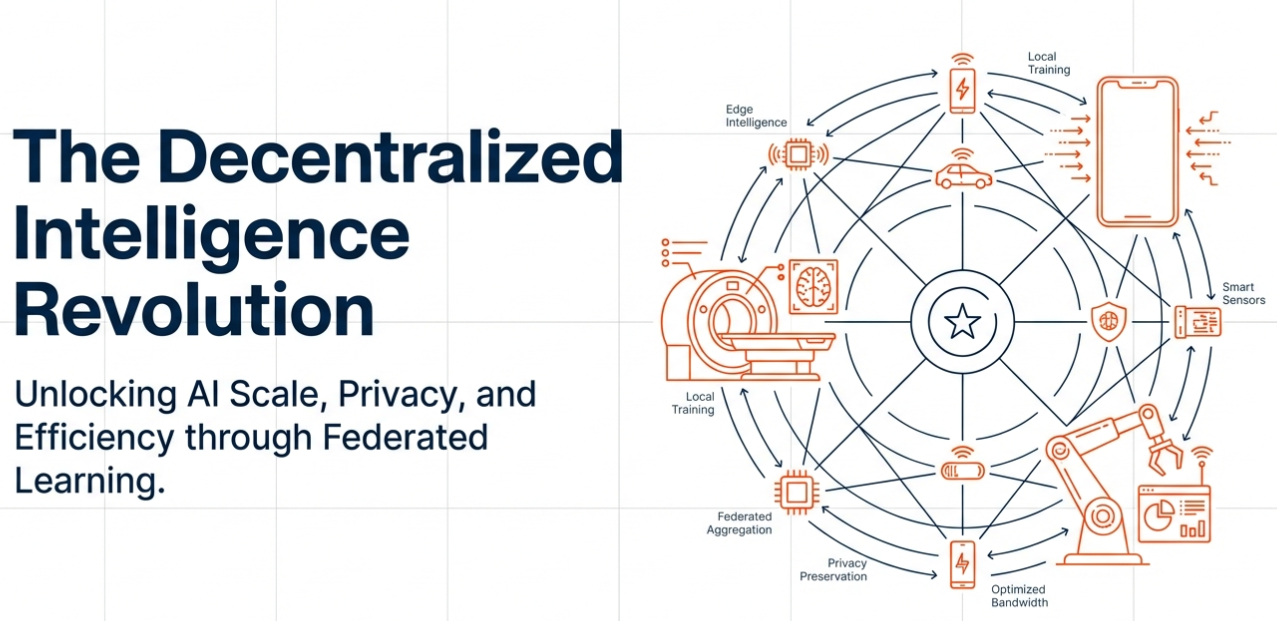

Multi-site Federated Intelligence. 10x faster model deployment to 1000s of devices. Defect detection <200ms. 60% labour cost reduction. Manage, deploy, and monitor ML models on fleets of devices. Connect your cameras, sensors, and gateways, stream data to the cloud, train models, and roll out updates over‑the‑air—securely and at scale.

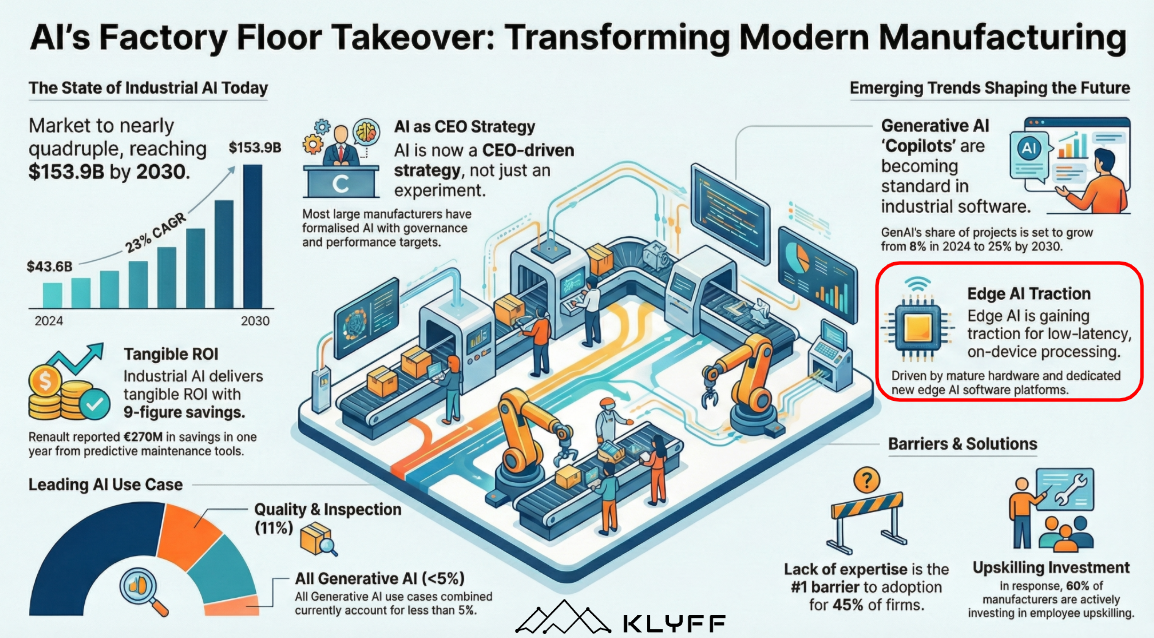

Traditional AI Solutions don't work

Why Manufacturers Choose Klyff

Traditional AI solutions fail. Your business needs measurable ROI

The Deployment Problem

- Traditional cloud platforms take 6-12 months

- Months of engineering to optimize models

- Vendor lock-in increases ongoing costs

The Hidden Costs

- Model optimization requires specialized talent

- Moving data to cloud = bandwidth costs

- Privacy concerns with sensitive manufacturing data

The Opportunity

- Deploy AI to the edge in 4-8 weeks

- 50-70% faster inference on edge devices

- Full control of data & models

- Demonstrable ROI within weeks

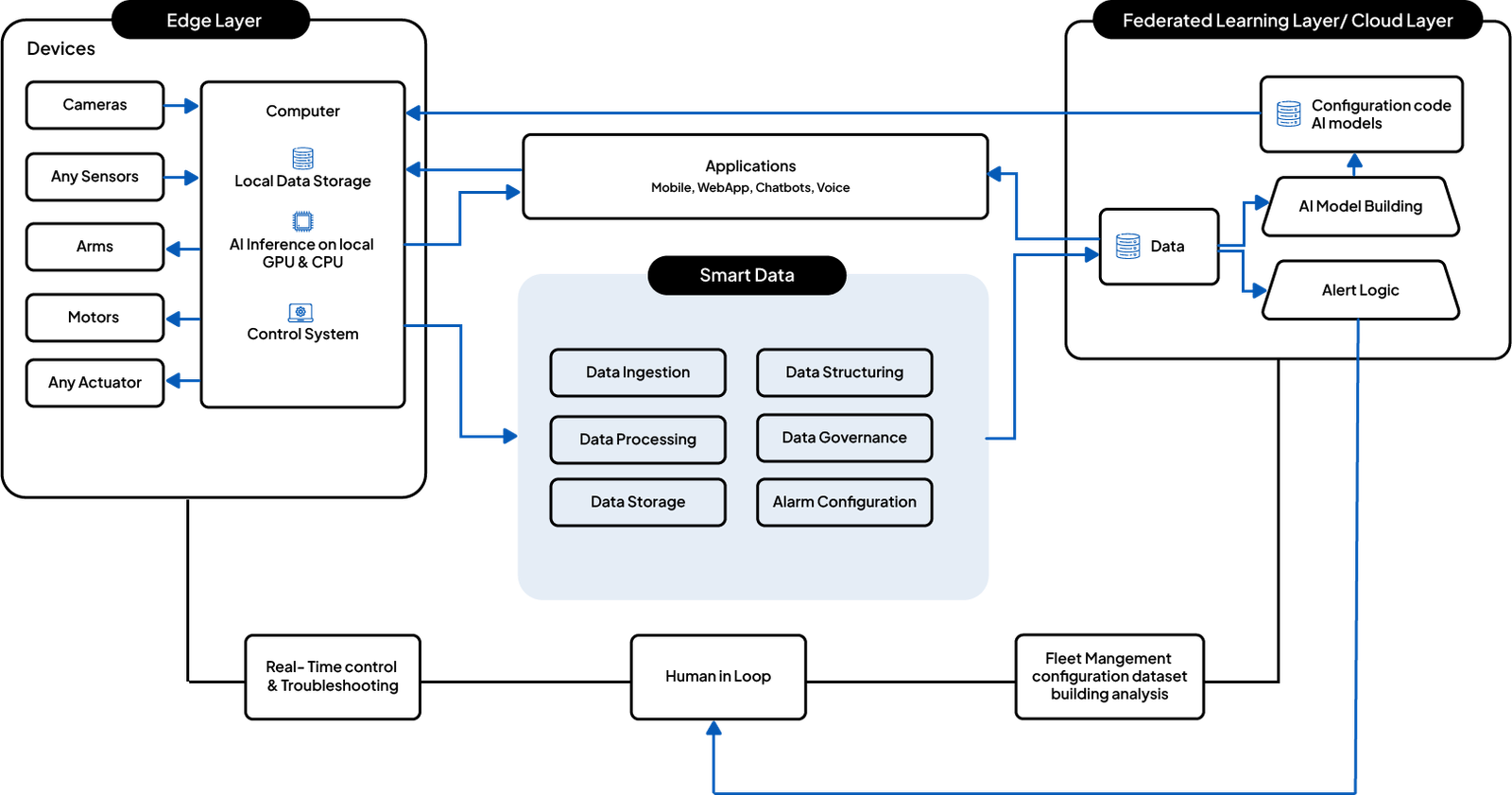

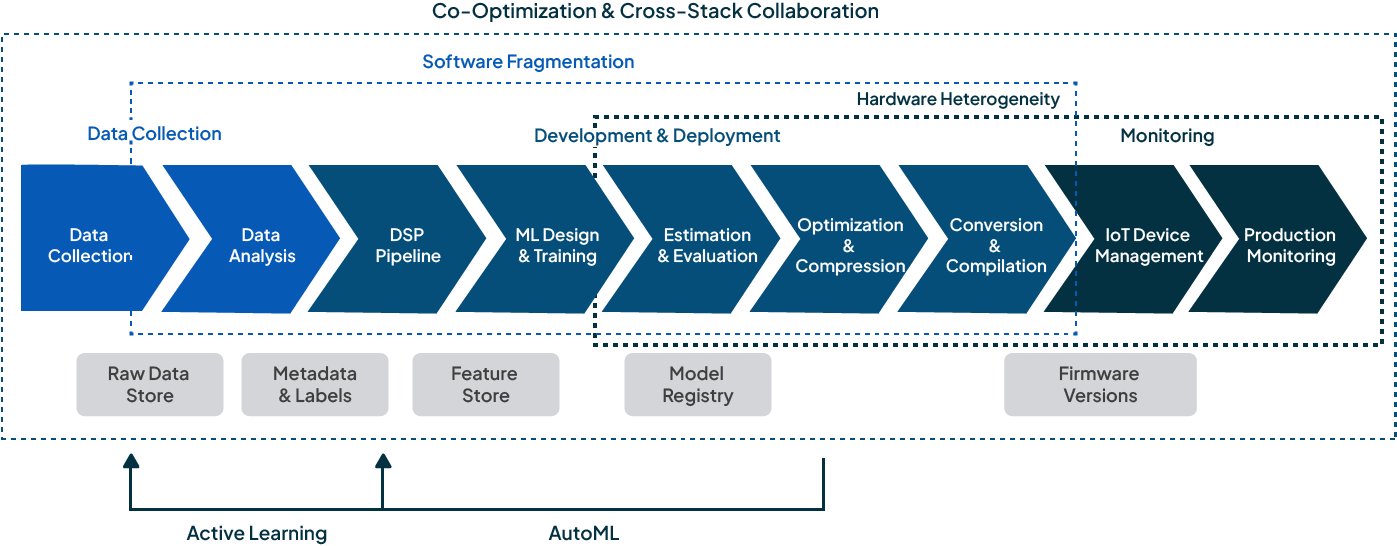

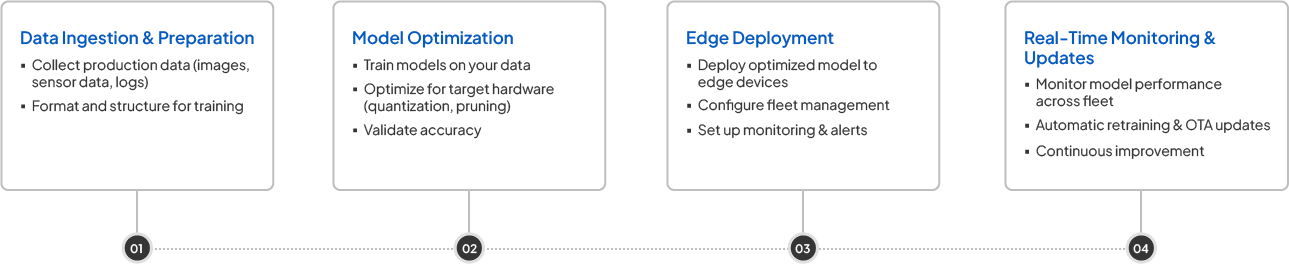

How Klyff Works

Klyff is Certified and Optimized for

Why Klyff Matters

Manufacturing Leader's Choice

We have your back. We ensure success for the organization and the leader.

Rapid ROI

- Deploy in 4-8 weeks v/s 6-12 months with cloud

- Deploy defect detection, predictive maintenance, and fleet intelligence 10x faster than cloud-first platforms. Go live in weeks, not months.

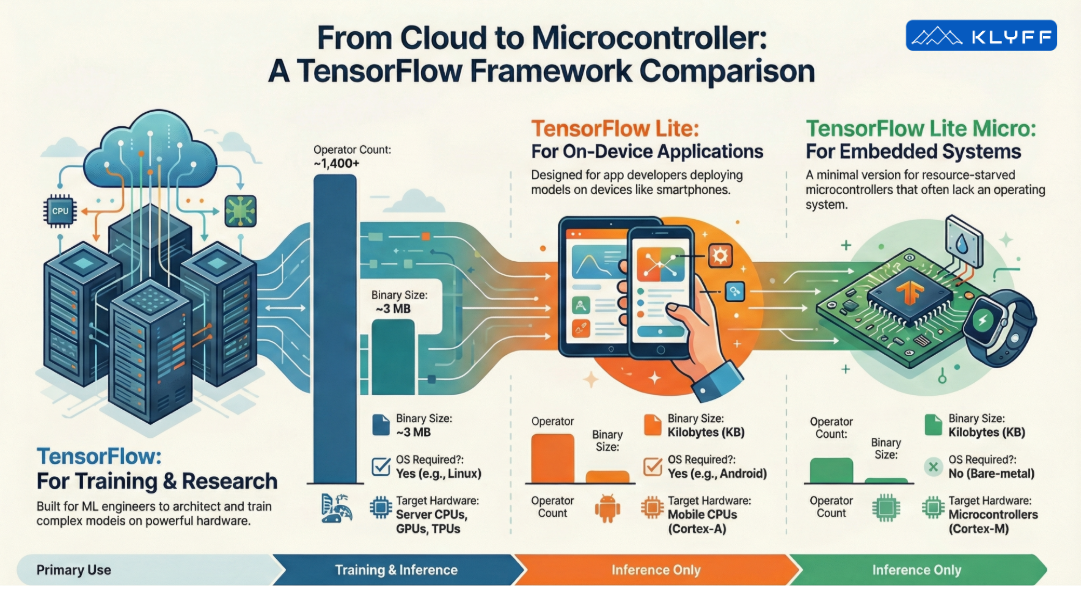

Efficient

- 50-70% Performance Improvement with 70-80% Size Reduction

- Our KlyffRT optimization and hardware-specific tuning delivers faster inference, lower latency, and superior accuracy. No cloud round-trips needed.

Open

- Zero Vendor Lock-in, Certified on 10+ platforms

- YOUR models, YOUR hardware, YOUR data.

- Deploy on NVIDIA Jetson, Google Coral, Intel, or any edge device. No proprietary APIs. Full control.

60% Less Cost

- 60% Cost Benefits and Zero Cloud Latency

- From None to minimal round trips to the cloud. Models refreshed with OTA across your entire fleet

Privacy First

- Your data never leaves the devices or your infrastructure. Fully compliant with SOC2 and ISO 27001 requirements

You are in good company

Our Engineers have proudly Served

and we are proud partners with

Selected Customer Success Stories

Adaptive Predictive Maintenance

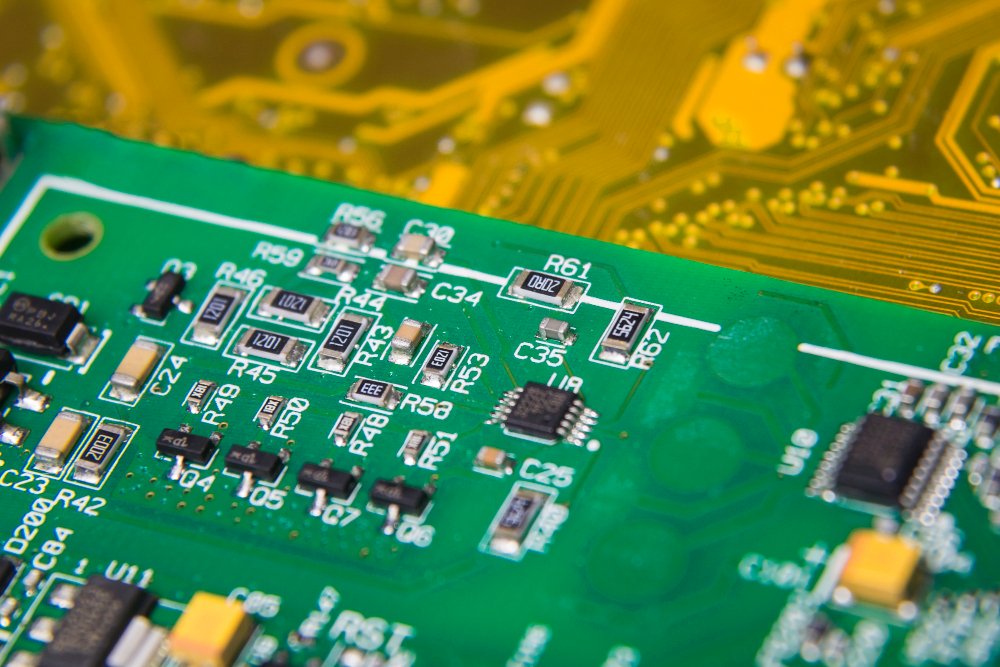

Solder Joint Inspection

PPE Compliance in Chemical Plant

Client Speak

The Platform and Team that forms the basis of our success

“With the Klyff platform, we can build on a reliable Edge AI infrastructure and a excellent team .

What was important to us was to be able to integrate sensors in an easy and fast manner through our project managers so that our client could easily manage the worker safety in the building”

Fale Connosco

Co-founder and CEO, LMGE