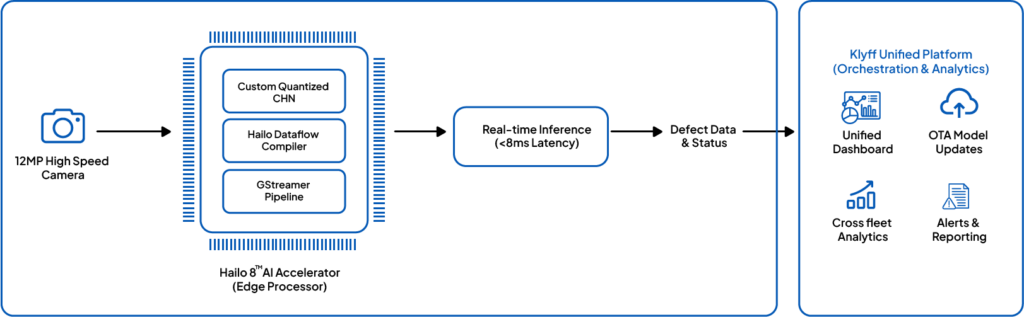

High-Speed Solder Joint Inspection

Hardware-Aware Model Optimization & NPU Acceleration

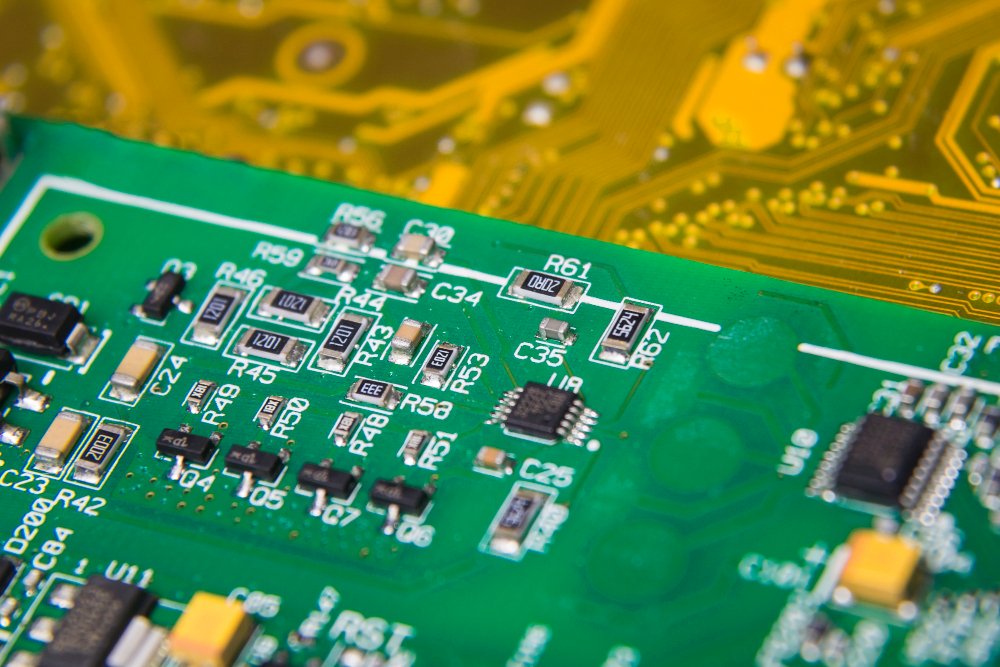

The Problem

A Tier-1 Electronics Manufacturing Services (EMS) provider was experiencing a 15% false-positive rate with their traditional Automated Optical Inspection (AOI). To maintain production speed, images were sent to a local server, but network congestion caused “latency spikes,” leading to line stoppages.

Solution

Klyff deployed a Custom Quantized CNN (Convolutional Neural Network) directly onto the camera’s edge processor. By performing inference at the “Glass” level, we eliminated the need for image transmission.

Hardware

Edge Processor: Hailo-8™ AI Accelerator integrated with an industrial PC.

Sensor: 12MP High-Speed Global Shutter Camera.

Software

Optimization: Hailo Dataflow Compiler (to convert the model to 8-bit integer format).

Pipeline: GStreamer with Klyff’s low-latency “Vision-Link” wrapper.

Results

- Latency: Reduced from 120ms (server-based) to 8ms (on-device)

- Accuracy: False-positive rate dropped to <2%

- Cost saving of an estimated $12,000/month in manual rework costs per line.

Solution Flow

Klyff gives a significant advantage over traditional Cloud IoT

Most IoT platforms are just “pipes” for data. Klyff is the intelligence at the end of the pipe. We focus on the Silicon-to-Model optimization unlike Cloud Dashboards

| Feature | Traditional Cloud IoT | Klyff "Hard Tech" (Edge-First) | The Klyff Advantage |

|---|---|---|---|

| Response Latency | 200ms – 2 seconds (Cloud Round-trip) | < 10ms – 20ms (On-Device Inference) | 10-50x Faster. Essential for high-speed safety stops and robotics. |

| Data Transmission Costs | High. Constant streaming of raw sensor/video data. | Near-Zero. Only anomaly "events" are sent to the cloud. | 90% Cost Reduction. Saves thousands in cloud egress and storage fees. |

| Data Privacy & Security | High Risk. Raw sensitive data travels over the public internet. | Secure by Design. Raw data never leaves the device; only insights move. | GDPR/Union Compliant. Ideal for worker monitoring and IP-sensitive zones. |

| Connectivity Reliance | System fails or "freezes" if Wi-Fi/4G drops. | 100% Autonomous. Decisions continue even during network outages. | Critical Reliability. No downtime for remote mines or offshore assets. |

| Hardware Efficiency | Heavy data logging drains battery and bandwidth. | Hardware-Optimized. Uses NPUs/FPGAs to run AI at 10,000x higher efficiency. | Extended Asset Life. Models run on ultra-low-power $5–$20 chips. |

| Failure Detection | Reactive. Alerts you after a threshold is crossed. | Proactive. Identifies "micro-drifts" in machine behavior weeks earlier. | True Predictive Maintenance. Moves from "alerting" to "preventing." |

Other Case Studies

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection