Adaptive Predictive Maintenance

On device inference becomes inaccurate with each passing day. Your devices need to learn everyday in order to stay relevant. Most companies would build the model, deploy and let it run. Klyff would do on-device training to keep your models accurate.

The Problem

A manufacturer of industrial pumps found that their “failure detection” models became inaccurate after 6 months because the machines aged and their “normal” vibration signatures shifted. Standard models required manual retraining in the cloud.

Solution

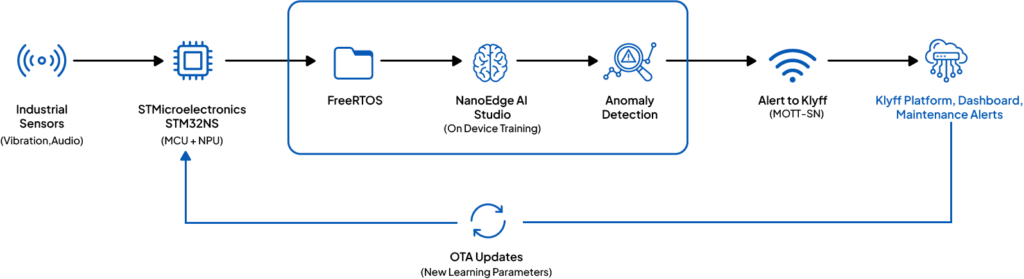

The “Hard Tech” Solution: Klyff implemented a Continual Learning loop directly on the ARM Cortex-M7 gateway. The system used Online Anomaly Detection to learn the machine’s new “baseline” every 30 days without sending raw vibration data to the cloud.

Hardware

MCU: STMicroelectronics STM32N6 (the first MCU with an integrated NPU)

Alternative NXP i.MX93 (includes the Ethos-U65 microNPU).

Sensors: Industrial-grade high-frequency vibration sensors (e.g., Bosch BMA456)

Alternative Ultrasonic microphones (e.g., Knowles SPH0641LU4H).

Software

Inference/Training: STM32Cube.AI (to convert models to C code)

OS: FreeRTOS (or Zephyr Project) (industry standards for deterministic performance).

Libraries: NanoEdge AI Studio (specifically designed for on-device learning without needing massive datasets).

Results

- 40% reduction in false positives, leading to better ROI

- Automatic model updates, thus freeing up valuable stakeholder and engineering time

- Continual learning to keep the model accurate

Solution Flow

Other Case Studies

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection