Edge MLOps as a Service

Teams wanting hands-off 24×7 operations

What we do:

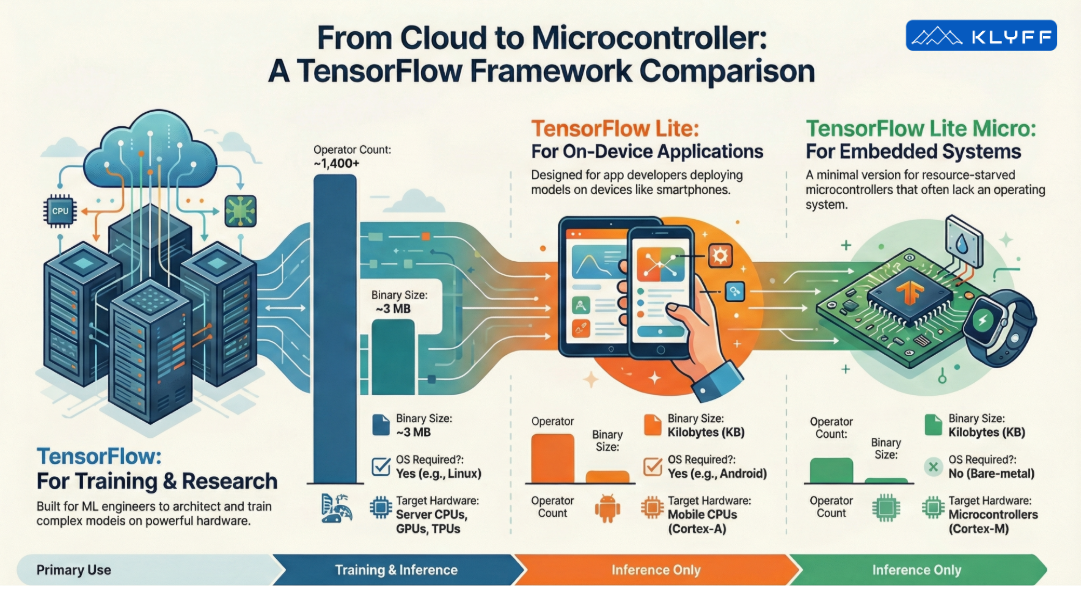

Klyff platform & model deployment

Klyff handles end-to-end deployment of optimized AI models across your entire fleet—from containerization and hardware-specific compilation (TensorRT for Jetson, TFLite for Coral, OpenVINO for Intel, etc.) to device provisioning and initial validation.

We manage all low-level details, including runtime configuration, dependency management, and failover logic, so your teams can focus on manufacturing operations rather than DevOps complexity.

Deployment is automated, reproducible, and auditable, ensuring consistent behaviour across all devices in your fleet.

Fleet monitoring (100+ devices)

Klyff provides real-time visibility into the health and performance of every edge device in your fleet—CPU/GPU utilization, memory consumption, model inference latency, accuracy drift, and device temperature.

Anomalies (stuck processes, resource exhaustion, inference timeouts) trigger automatic alerts and diagnostic logs, enabling rapid triage and preventing cascading failures.

Historical telemetry is logged for trend analysis and capacity planning as you scale to additional sites or production lines.

Model versioning & OTA updates

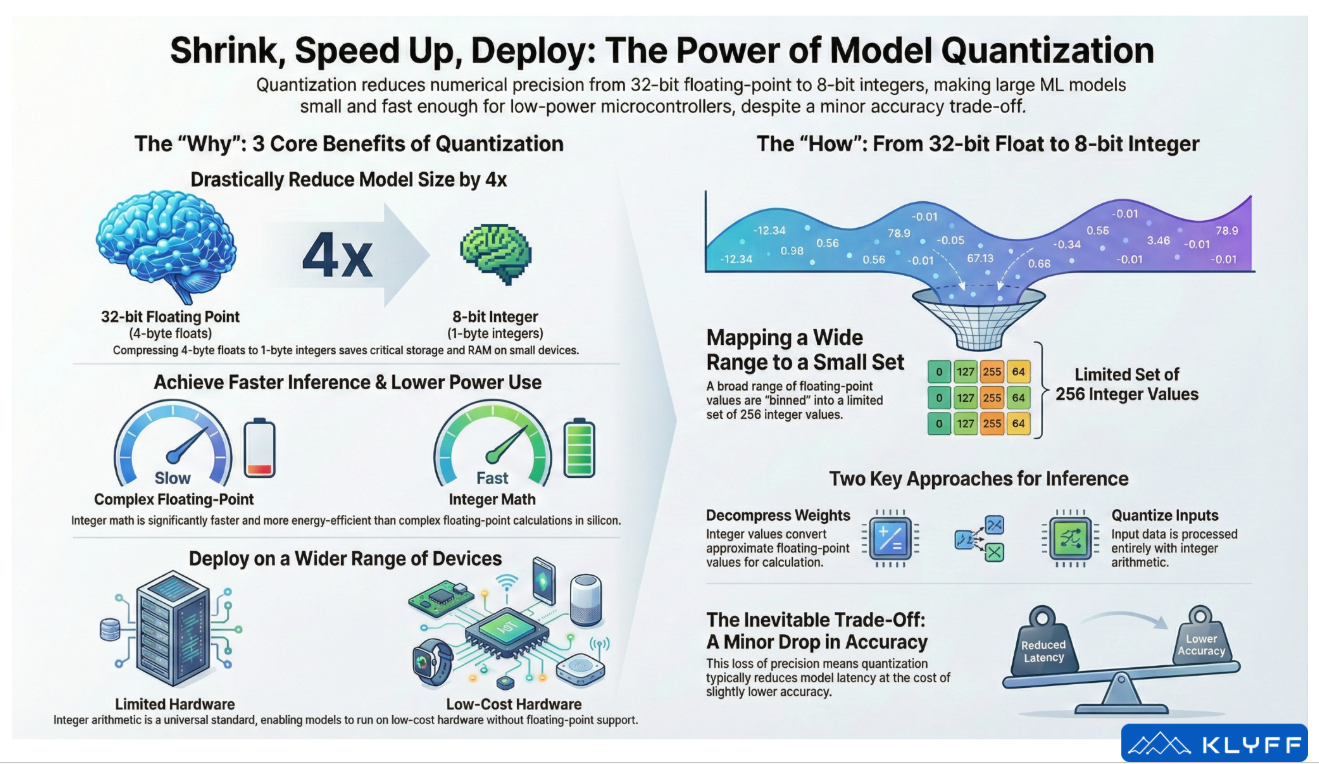

Every model iteration—whether from retraining, quantization adjustments, or accuracy improvements—is rigorously versioned with metadata (training date, validation metrics, hardware compatibility).

Over-the-air (OTA) updates are staged: new models are first validated on a subset of devices, performance metrics are reviewed, and only after sign-off are updates rolled out to the entire fleet.

Rollback to previous versions is instant, ensuring zero downtime and reducing risk if an update degrades performance.

Automatic retraining triggers

Klyff monitors model performance in production and automatically initiates retraining when accuracy drifts below thresholds, new defect classes appear, or seasonal/process changes alter the data distribution.

Retraining pipelines are fully automated—data collection, feature engineering, model training, validation, and staged deployment—minimizing manual intervention and ensuring models stay calibrated to your current production reality.

You set high-level policies (e.g., “retrain monthly or if accuracy drops below 92%”), and the system executes them autonomously.

Performance dashboards

Klyff provides executive and technical dashboards tailored to different stakeholders: quality managers see real-time defect rates and trends, maintenance teams see anomaly predictions and asset health, and engineers see model accuracy, inference latency, and hardware utilization.

Dashboards include SPC charts, trend analysis, and drill-down capability to individual images or sensor logs for root-cause investigation.

All data is encrypted, compliant with your data governance policies, and accessible via web or mobile interfaces.

24×7 support

Klyff’s dedicated support team provides round-the-clock monitoring, troubleshooting, and escalation for production issues—model accuracy degradation, device failures, integration gaps, or deployment problems.

Support includes hotline access, remote diagnostics, and prioritized responses to critical issues affecting production uptime.

Escalations to Klyff’s engineering team for complex issues are handled transparently with clear ETAs and regular status updates.

Monthly optimization reviews

Every month, Klyff’s data scientists and engineers conduct deep-dive reviews of your fleet’s performance—analyzing inference latency trends, accuracy metrics, hardware utilization, and emerging defect patterns.

These reviews identify optimization opportunities: model compression that trades 0.5% accuracy for 30% latency improvement, hardware configuration tuning, or retraining on new failure modes.

Actionable recommendations with estimated impact are presented to your team, driving continuous incremental improvements to ROI and operational efficiency.

Expected outcomes:

Fully Managed

Edge ML Infrastructure

Hands Off

Model Lifecycle

Ongoing

Continuous Improvement

99%+

Uptime guarantees

Perfect For:

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection