Quality Inspection Implementation

Quality teams want defect detection within 8-12 weeks

What we do:

Custom model training on your defect images

Klyff takes your proprietary defect images—surface scratches, solder joint failures, paint imperfections, packaging damage—and fine-tunes pre-trained vision models (YOLO, ResNet, EfficientNet) on your specific defect classes, achieving 95%+ accuracy in 2–4 weeks.

Transfer learning from public datasets accelerates training and reduces the need for massive labelled datasets; your domain-specific images dramatically improve precision over generic models.

The result is a production-ready model tailored to your exact manufacturing process, defect types, and image conditions.

Dataset preparation & annotation (if needed)

If your images are not yet labelled, Klyff handles annotation—drawing bounding boxes or segmentation masks around defects—using a combination of automated pre-annotation (to speed labelling) and human review to ensure quality.

We validate dataset splits (train/val/test), check for class imbalance, and remove ambiguous or low-quality samples that would degrade model robustness.

The final annotated dataset is versioned and delivered to you with a data manifest, ensuring reproducibility and transparency for future retraining.

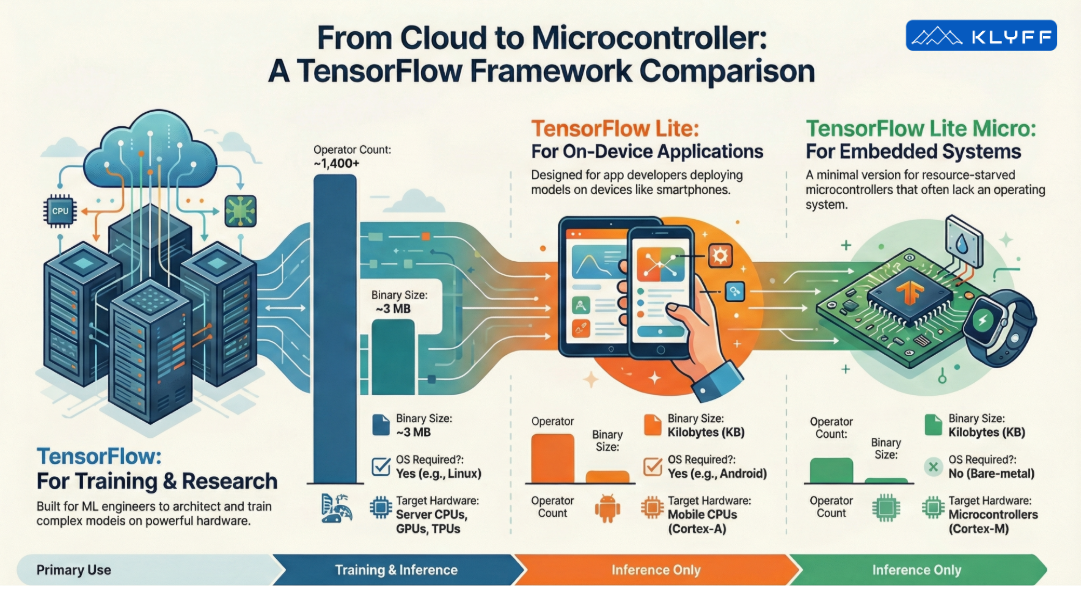

Deployment to your edge devices

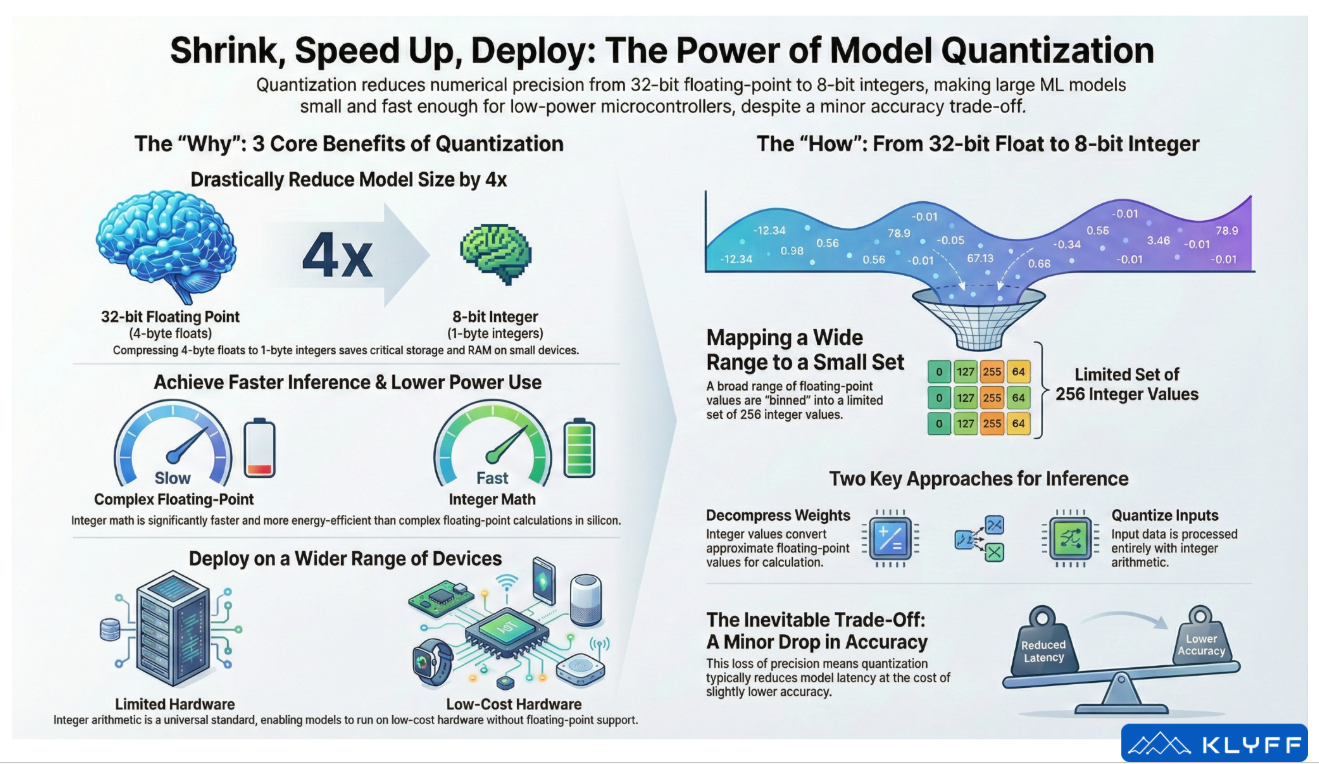

Once the model is trained and optimized, Klyff compiles it for your chosen hardware (NVIDIA Jetson, Google Coral, Seeed reComputer, Arduino, etc.) using the appropriate conversion pipeline (TensorRT, TFLite, OpenVINO, ONNX).

We handle all low-level details—quantization, layer fusion, and runtime configuration—and validate end-to-end latency and accuracy on your actual devices in your factory environment.

Deployment is typically 2–4 weeks, including hardware setup, software containerization, and failover/redundancy configuration.

Integration with existing quality systems (dashboards, alerting)

Klyff integrates defect detection outputs with your existing infrastructure—MES (Manufacturing Execution Systems), ERP (SAP, Oracle), SCADA, or custom dashboards—via APIs, MQTT, or database connectors, eliminating data silos.

Real-time alerts notify operators immediately when defects exceed thresholds, with visual evidence (annotated images), defect coordinates, and confidence scores to speed root-cause investigation.

Historical defect trends are logged for SPC (Statistical Process Control) and continuous improvement.

Team training & documentation

Klyff provides hands-on training for your operators, engineers, and quality teams on model performance interpretation, alert response procedures, and ongoing maintenance (retraining, threshold tuning, hardware troubleshooting).

We deliver complete documentation—architecture diagrams, API specs, troubleshooting guides, and runbooks—so your team can manage the system independently and confidently scale to additional production lines.

Optional ongoing support packages ensure rapid response if the model drifts or hardware issues emerge.

Expected outcomes:

90%+

Defect detection accuracy

100%

End-to-End Production ready system

100%

Team trained on operations and maintenance

100%

Documentation and Support guides

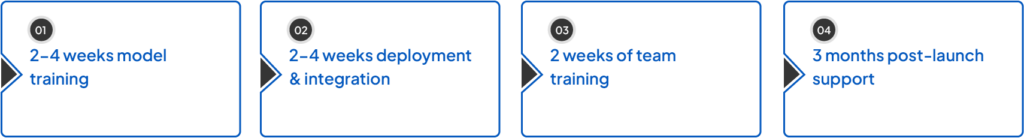

Our engagement process:

Selected Customer Success Stories

Adaptive Predictive Maintenance

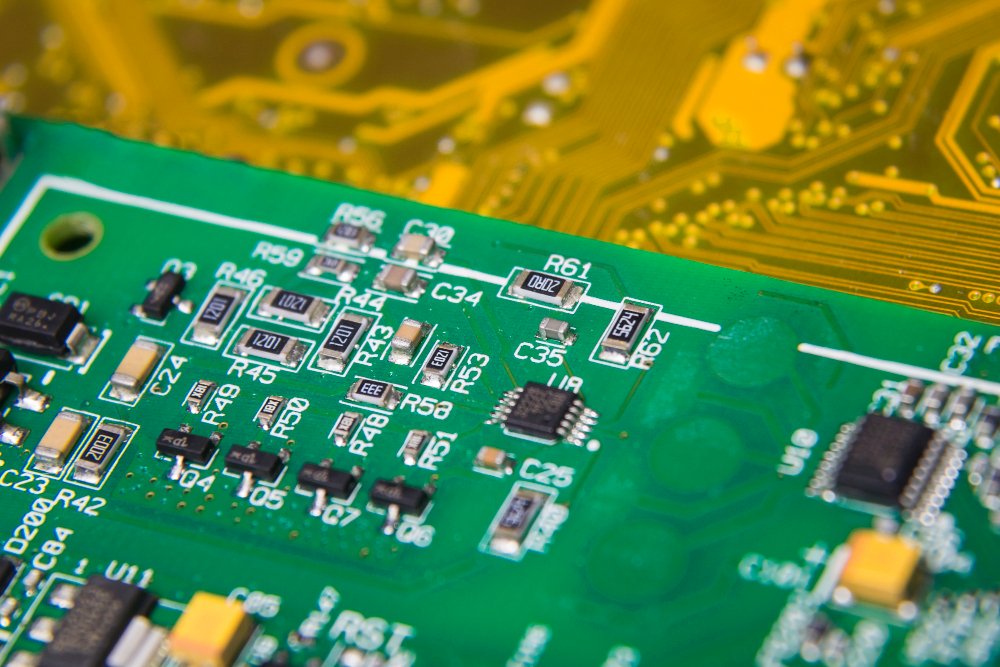

Solder Joint Inspection