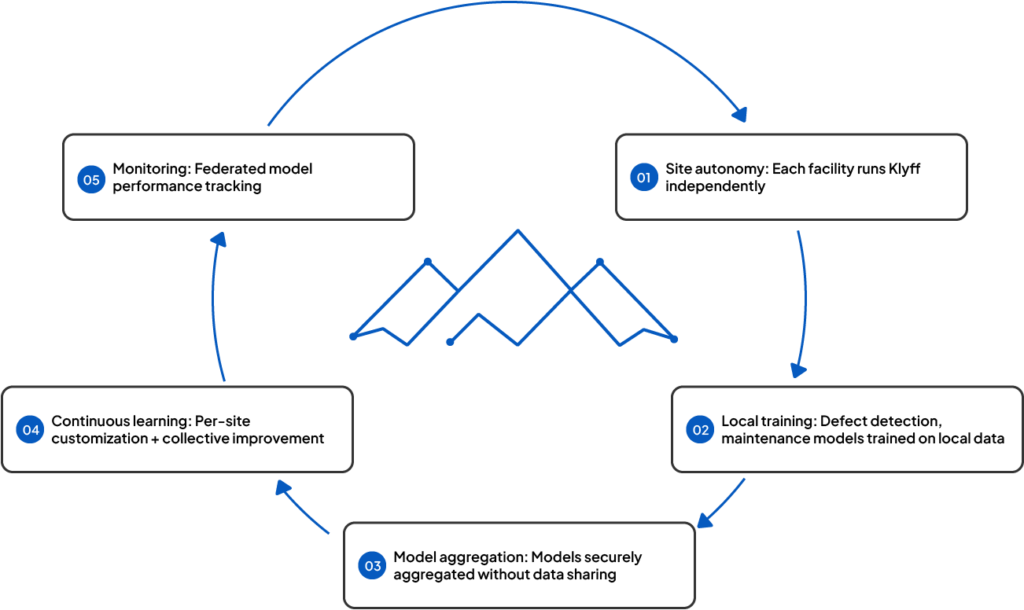

Federated Learning for Multi-Site Intelligence

Privacy-preserving AI across multiple factories

Problem Statement

Large manufacturers with multiple sites want to learn collectively from each facility’s data. But data privacy, governance, and security concerns make centralized data lakes impractical. Federated learning is the solution.

Solution

Klyff federated learning enables each site to train locally on its own data, then aggregate models without sharing raw data. Collective intelligence + complete privacy

Zero

Data movement costs

50%+

Reduction in data governance complexity

40%+

Faster model improvement (vs. single-site)

100%

Full GDPR/HIPAA compliance

How It Works

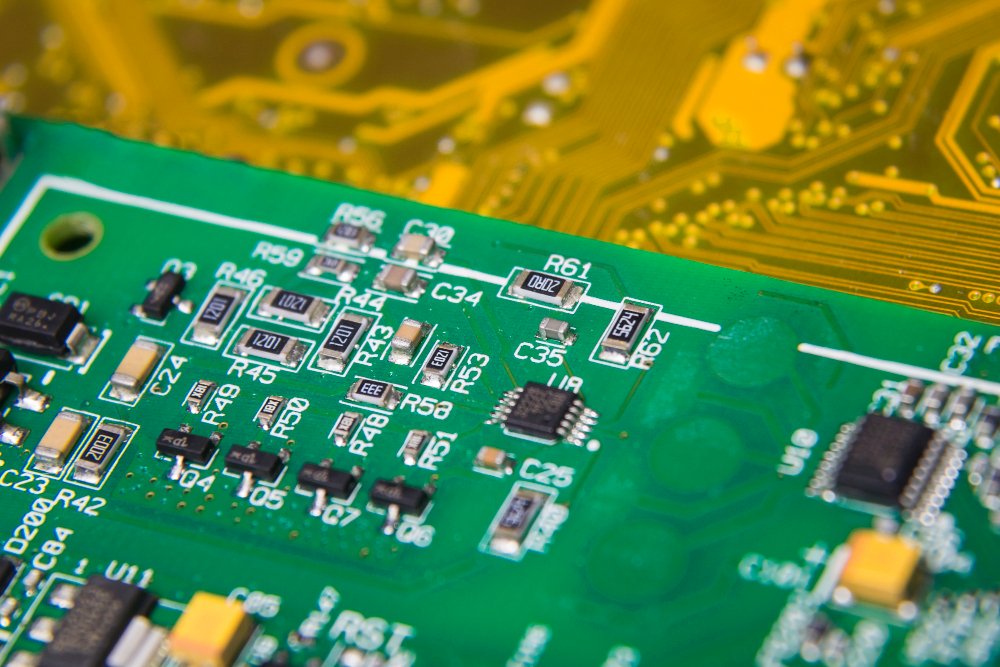

PCB Assembly Sites

Learning optimal inspection across multiple plants

Automotive manufacturing

Defect detection standardization

Food & beverage

Quality control across regions

Pharmaceutical

Compliance across facilities

Case Study

Company: Global EMS Manufacturer

Industry: Electronics Contract Manufacturing (8 global facilities)

Challenge: Inconsistent defect detection across sites; data privacy concerns with centralized ML

Solution: Klyff federated learning across 8 manufacturing sites

Results:

- 35% improvement in defect detection accuracy (collective learning)

- $0 data movement costs (vs. $50K/month with cloud)

- Full data sovereignty (zero data leaves each facility)

- Standardized quality metrics across regions

“With the help of Klyff we now have centralized learning over our 8 manufacturing sites. This collective intelligence with privacy control made sure that we are not in the dark with important decisions”

— John Miller, Quality Director, EMS Manufacturing

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection