Predictive Maintenance on Edge

$250K-$500K annual savings per production line

Problem Statement

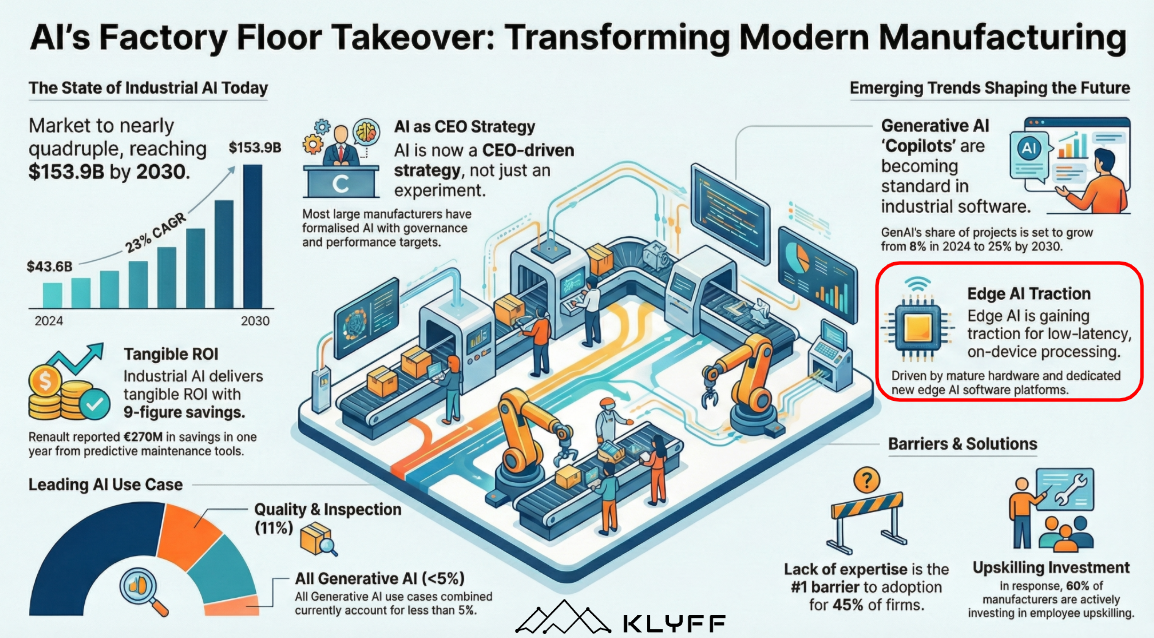

Unexpected equipment failures cost manufacturers millions in lost production. Reactive maintenance is expensive. Preventive maintenance over-services. Predictive maintenance is the answer—but traditional cloud approaches are slow and expensive.

Solution

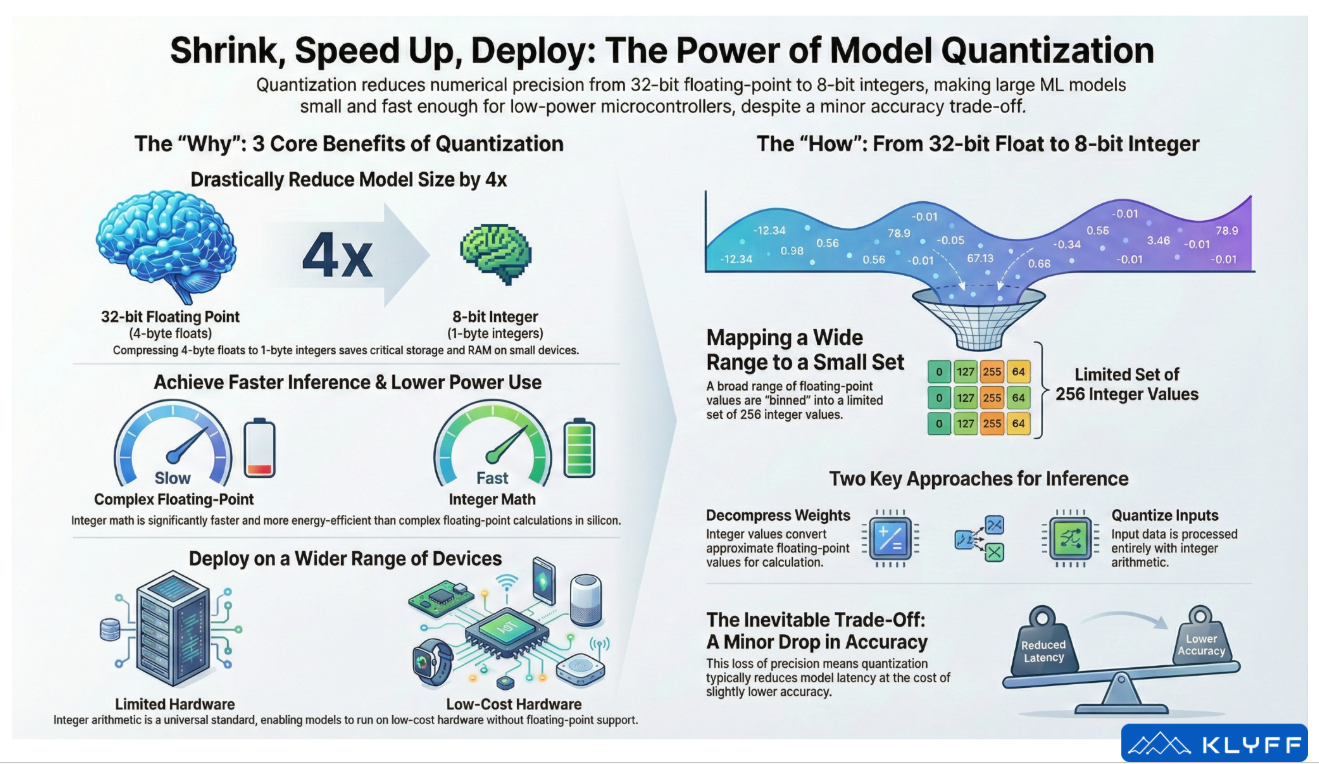

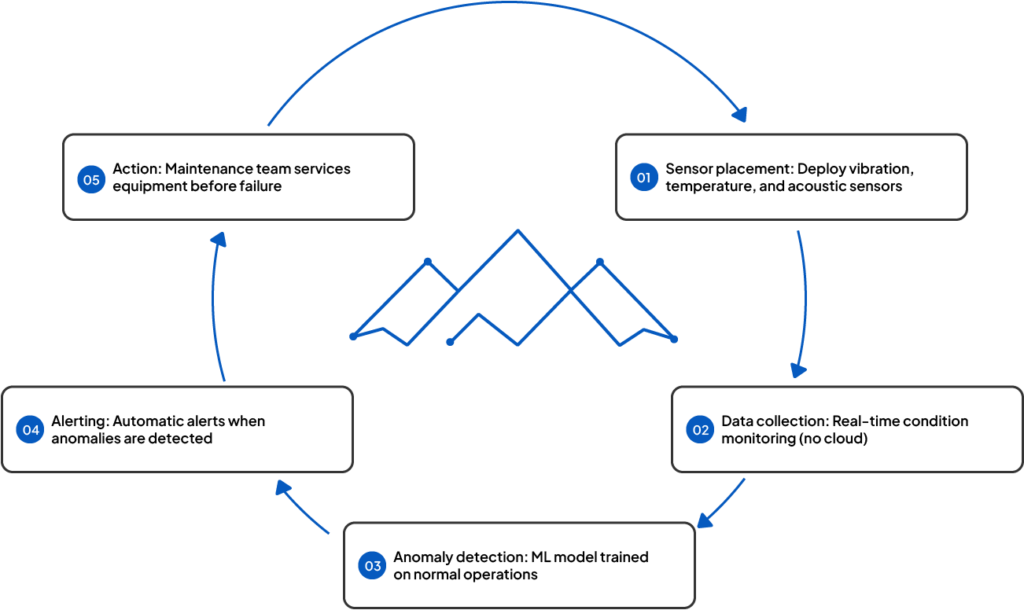

Klyff enables on-device predictive maintenance. Continuous condition monitoring (vibration, temperature, acoustic) with ML-powered diagnostics. Detect equipment stress before failure—without cloud costs.

$250K-$500K

Annual savings per production line

70%

Reduction in Unplanned Downtime

6 Months

Payback period thus resulting in immediate ROI

15-20%

Improved production efficiency

How It Works

Rotating machinery Pumps, Motors, Compressors

Conveyor systems and belt drives

Gearboxes and bearing assemblies

Production line equipment

HVAC & facility systems

Case Study

Company: Industrial Manufacturing Plant

Industry: Heavy Equipment Manufacturing

Challenge: $150K/month in unplanned downtime from pump and motor failures

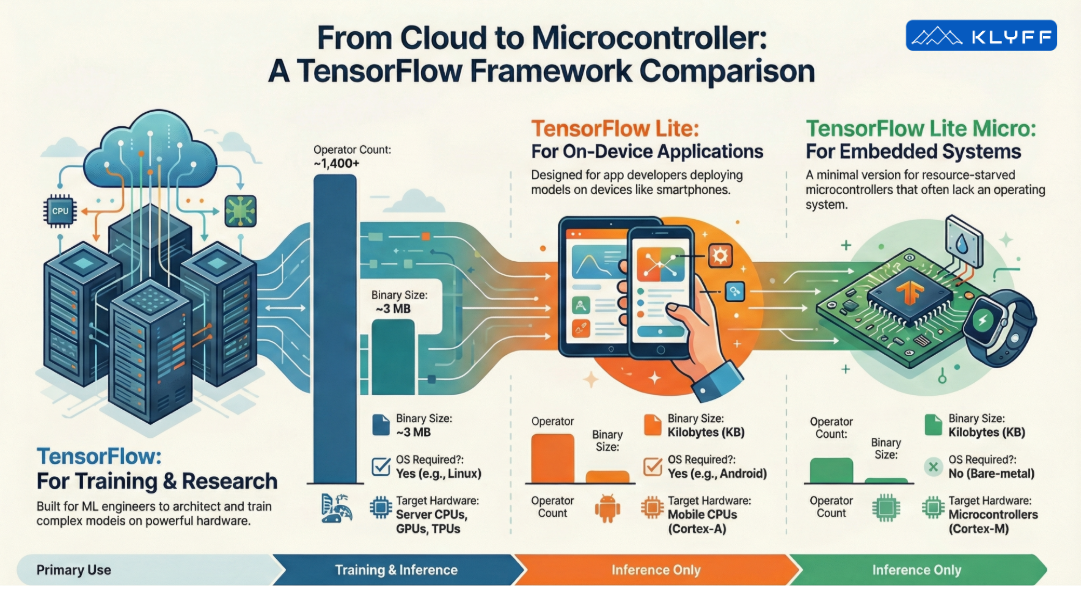

Solution: Klyff predictive maintenance on 20 edge devices (STM32H7 microcontrollers)

Results:

- 70% reduction in unplanned downtime

- $400K annual savings

- 3-month ROI

- Early detection prevented 12 critical failures (worth $500K+ in lost production)

“The ROI was obvious within the first 2 months. We caught a failing pump 2 weeks before it would have stopped production completely. That one detection paid for the entire system.”

— Operations Manager, Industrial Manufacturing

Selected Customer Success Stories

Adaptive Predictive Maintenance

Solder Joint Inspection