Industrial IoT

Stay ahead of your competition with Industry 4.0. Propel a 20% increase in shop floor productivity, a 30% increase in machine uptime, and a drastic reduction in maintenance and repairs of high capital assets with smart manufacturing or an industrial IoT solution.

The need

Ready for Industry 5.0

Provision new devices, manage their lifecycle, receive and store telematics and sensor data in the cloud, execute remote commands, run over-the-air (OTA) updates, analyze device data, and create rules for smart alerts.

Out-of-the-box connectivity and data processing features utilize popular protocols such as MQTT and can be used together with popular data management systems and databases to integrate with your existing backend.

Use cases

Make your machines and processes efficient with real-time factory insights

Machine Monitoring

Health, speed, output, energy consumption, and other health indicators. Uptime and downtime, actual operation time against scheduled available hours to optimize production schedules.

Production Line Monitoring

Gain insights into the cause, duration, and frequency of interruptions. Identify bottlenecks and optimise workflows. Compare projected and actual outputs to assess the effectiveness of production planning. Monitor reject rate.

Overall Equipment Effectiveness

Determine the availability, performance, and quality of industrial equipment. Compare OEE of industrial equipment with established standards to identify areas for improvement and set performance targets.

Predictive Maintenance

Analyse real-time data on the health and performance of industrial assets from any location. Proactively prevent equipment failures and extend the life span of assets.

Compliance & Regulation

Build trust and minimise legal and regulatory risks. Track and record product production history, making it easier to identify and address quality issues

Sustainability

Measure, track, and manage the release of carbon dioxide (CO2) and other greenhouse gases. Access real-time insights into the volume and types of industrial waste you create and reduce your environmental impact.

Why Klyff

Harness the potential of your manufacturing operations

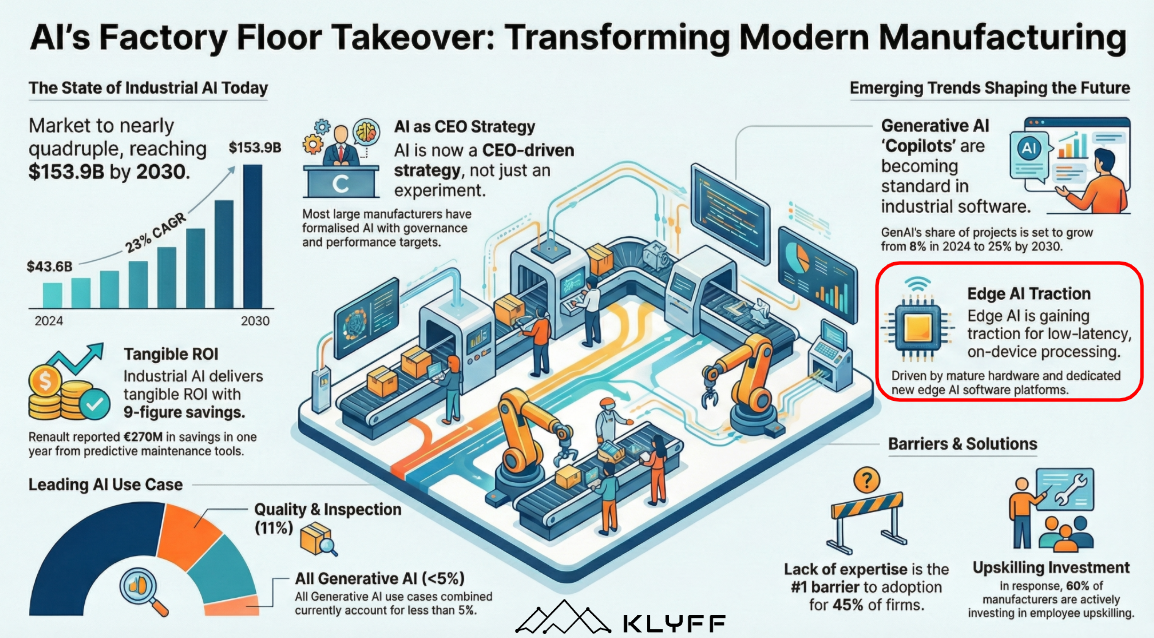

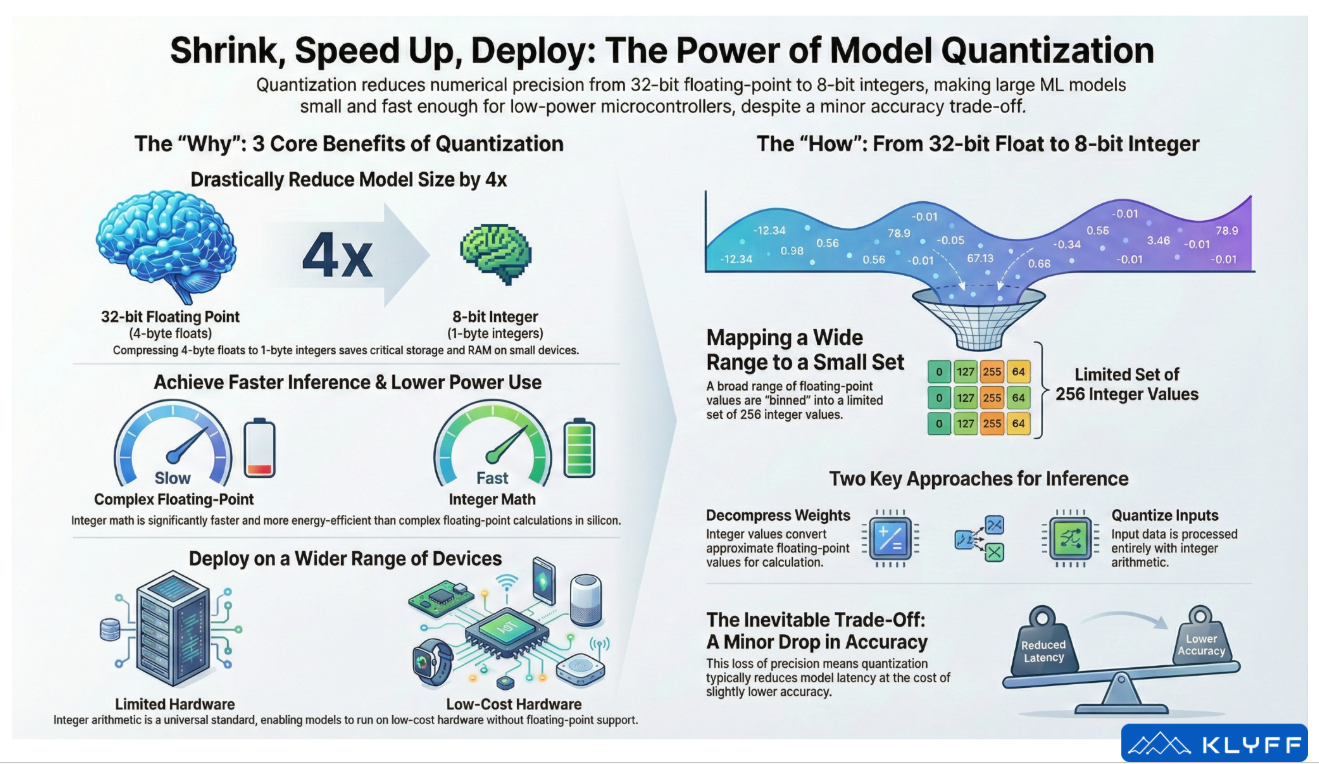

Industrial IoT platform is a rapidly growing segment of IoT technology comprising a collection of functions for edge device management, IoT data analytics, modern sensor technologies, and connectivity solutions that enhance industrial equipment and industrial operations with remote monitoring, predictive maintenance, and extensive device data analytics.

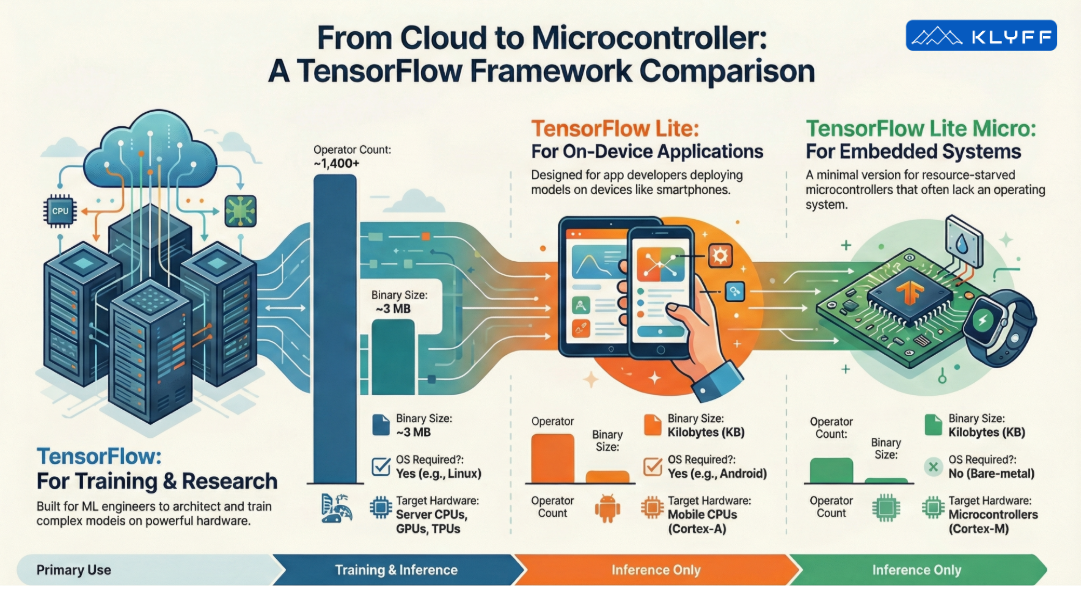

AI models and Firmware Upgrades

Remote model deployment and firmware upgrades over the air to roll out new features and security patches

Easy Real-Time Dashboards

Visually appealing information radiators for all aspects of management

Integration

Integrated with existing building management systems

Extensive Connectivity

Connect with a wide variety of devices in your building via the following built-in protocols: HTTP, CoAP, MQTT, LwM2M, and SNMP.

Scalability & Availability

All platform components are horizontally scalable. Klyff has production deployments supporting more then 500,000 devices connected.

LoRaWAN & SigFox Support

Connect LoRaWAN devices via integrations with standard network servers like TTN, LORIOT, ChirpStack, Actility, etc. Connect SigFox devices via integrations with the SigFox backend.

Mobile Application

You are never too far from your facility with all the functionality available in the palm of your hand

Peace of mind

Maximised efficiency, reduced downtime, low operations costs, improved decision making and full security